An Introduction to Electric Motors Maintenance

Electric motors are the backbone of many industrial, commercial, and residential systems, powering everything from fans and pumps to large manufacturing machinery. Proper maintenance is essential to ensure that motors operate efficiently, reduce downtime, and extend their lifespan. This introduction provides an overview of best practices for maintaining electric motors to ensure smooth and reliable operation.

Key Maintenance Practices

-

Visual Inspections: Regularly inspect motors for visible signs of damage, wear, or overheating. Check for any unusual noises, vibrations, or odor that might signal a problem.

-

Cleaning: Dust, dirt, and debris can hinder motor performance and cause overheating. Clean the motor housing and vents using a vacuum or soft brush to ensure proper airflow.

-

Lubrication: Moving parts, such as bearings, need proper lubrication to reduce friction and prevent wear. Regularly apply the recommended lubricant to avoid motor failure.

-

Electrical Connections: Ensure that all electrical connections are tight and free from corrosion. Loose connections can lead to arcing and overheating, which can damage the motor.

-

Temperature Monitoring: Overheating is one of the most common causes of motor failure. Regularly check the motor’s operating temperature, ensuring it stays within the manufacturer’s recommended range.

Dc Motors

Dc Motors Ac Motors

Ac Motors Universal Motors

Universal Motors AC Electric Pumps

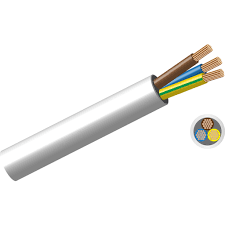

AC Electric Pumps Twisted Pair Cables

Twisted Pair Cables Single-Core Wire

Single-Core Wire Magnet Wires

Magnet Wires Fans

Fans Lights

Lights Refrigenerators

Refrigenerators

Reviews

Clear filtersThere are no reviews yet.